-Food and beverages: dairy products, latex, chocolate, syrup, cheese, wort, beer, soda water, cream, concentrated fruit juice, wort and fermented liquid.

-Fruit concentrates: pudding, jam, jelly and ketchup.

-Paste products: fat and grease etc.

-Cosmetics: face cream, detergent, hair style gel and essence oil etc.

-Medicine: extract, emulsion and pill liquid etc.

-Chemical industry: dye, fat, solvent, resin and polymer etc.

-Others: candy industry, baking industry and chemical industry etc.

Rotor pump when the 2 simultaneous reverse rotating rotors (with 2-4 gears) revolve, it produces suction force at the inlet (vacuum), which intakes the material delivered. The 2 rotors divide the rotor housing into many smaller parts and revolve in the sequence of a→b→c→d. When it revolves to position a, only housing Ⅰ is filled with medium; when it revolves to position b, housing B encloses part of the medium, when it goes to position c, housing A encloses medium, and finally it goes to position d, then housing A, B and Ⅱ are interlinked and the medium is transported to the outlet. As this process is repeated, medium (material) transported continuously.

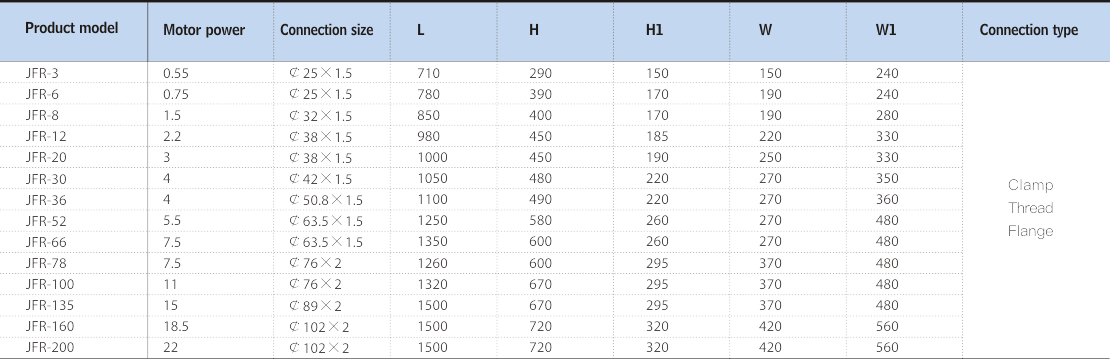

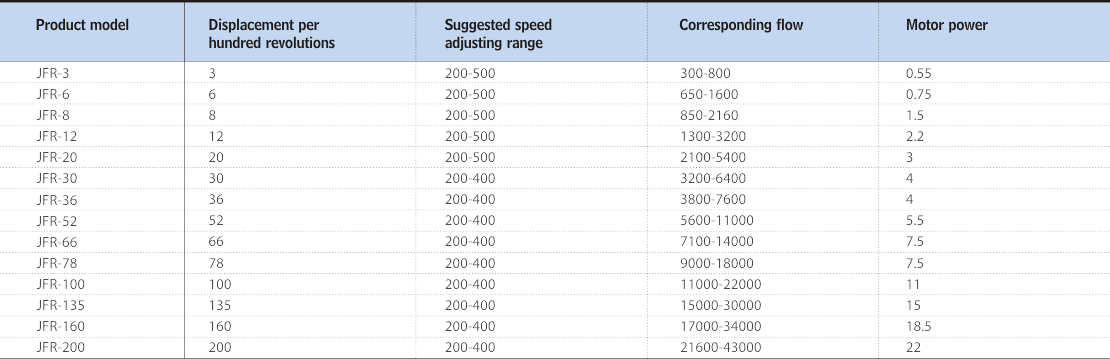

Note: The flow range in the table refers to the data measured when the medium is water.

Note: The flow range in the table refers to the data measured when the medium is water.

-The pump adopts stepless speed variator or frequency converter for speed adjustment within the range of 200~900rpm.

-When the pump conveys strong liquids of high viscosity, the motor power should be increased.

-For media with relatively poor flowability, it is suggested that the pump with matching flow should be used for conveying at the inlet.

-You will not be notified of any modifications to the data in the table. The parameters of the real products shall prevail.