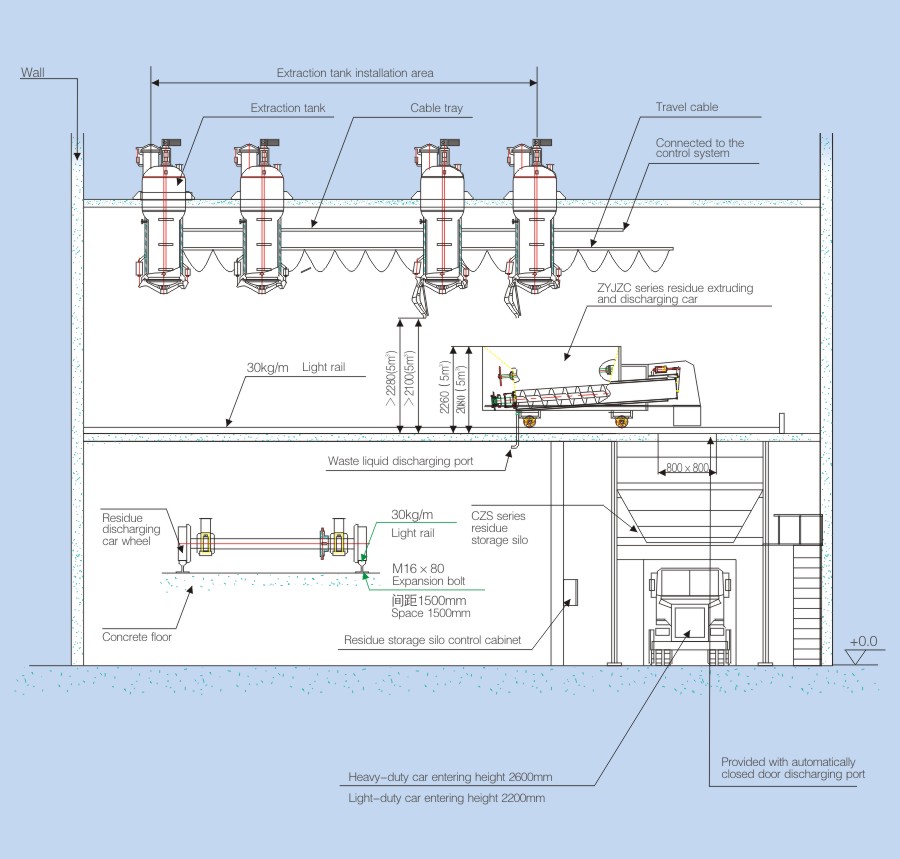

The whole system includes: automatic residue extruding and discharging car, track, material receiving port, liquid discharging device, cable tray, site control box (explosion-proof) and remote control box. The whole system is controlled by PLC human-machine interface. With such features as reliable running, simple operation, good sanitation and cleanliness, it has solved the problems of hard separation of TCM waste residues and waste liquids, hard removal and polluted environment. Meanwhile, the mode of handling TCM waste residues and waste liquids has been shifted from manual handling to automatic centralized handling through machine control. (The collected waste residues can be reutilized after filtration.) It improves labor intensity, enhances safety performance and protects environmental sanitation, conforming to relevant requirements in the GMP standard. It is currently a piece of preferred equipment for handling TCM waste residues in the extraction workshop of TCM manufacturers, realizing standard and modern TCM production management.

It is China’s first equipment that carries out TCM waste residue extruding and discharging simultaneously. The extruded medicine liquids can be reutilized after filtration.

Small residue discharging port at the residue car, which is only 1mx1m to the bottom discharging passageway. The hole on the floor is small and automatic door opening and closing can be realized to prevent the odor of medicine residues and steam from rising and free employees from any worries about safety.

The touch screen and PLC are adopted to realize automatic control. The special skid wire tray and flat cable tray are above 5 times the service life of other forms.

The residues are extruded to be dry, so that no dropping liquids will occur on the residue conveying car and the sanitation inside and outside the factory is protected.

When the extraction tank requires residue discharging, the touch screen will control the residue extruding and discharging car to run to the bottom of the extraction tank requiring residue discharging. Open the residue discharging door at the extraction tank and load the TCM waste residues into the residue storage hopper in the residue extruding and discharging car. Through touch screen automatic control, the residue discharging car is started and conveyed to the upper port of residue storage silo. Open the discharging door and start the residue extruding and discharging car to simultaneously separate the medicine residues and medicine liquids. The medicine liquids will enter the liquid storage tank (can be reutilized after filtration) or flow into the water treatment center. At the same time, the medicine residues will enter the residue storage silo on the first floor. After the waste medicine residues in the residue storage silo accumulate to a certain amount, run the conveying car to the bottom of the residue discharging door in the residue storage silo and open the residue discharging door in the residue storage silo in turn to load the TCM waste residues onto the conveying car and convey them to the garbage disposal plant outside the factory.

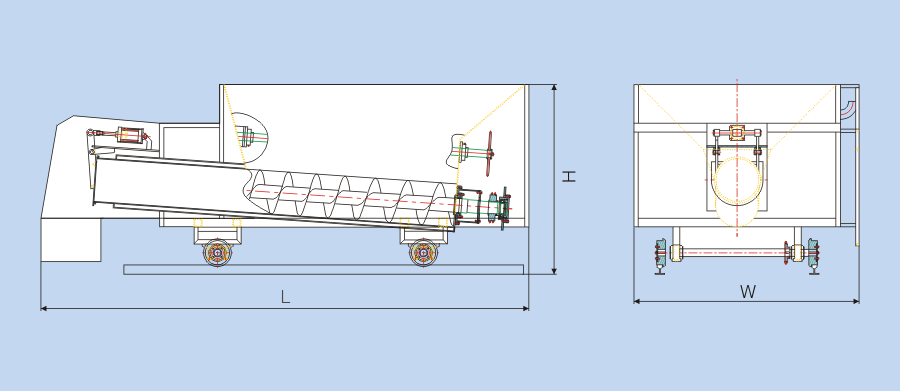

Note: The outline dimensions can be properly adjusted according to the situations at the site

The highest bearing capacity of pre-embedded steel sheet shall be selected according to equipment model.

The tolerance of verticality between the machine and the ground shall be no more than 3mm.

The space size of the pre-embedded steel sheet shall be selected according to the equipment