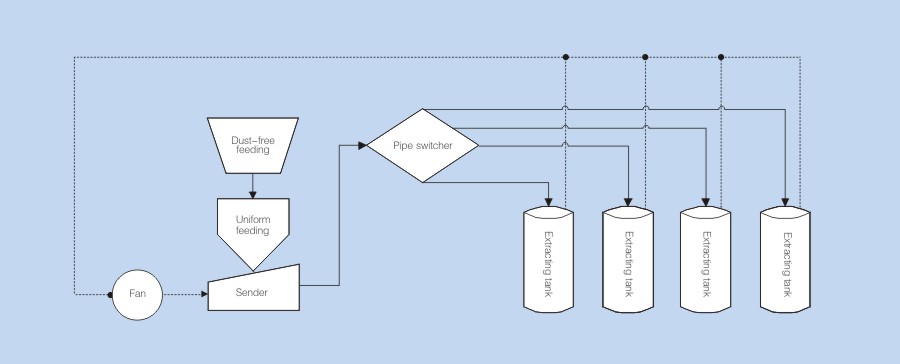

The automatic TCM raw materials air conveying system adopts wind power of the roots fan as the conveying energy and uses corresponding feeding technology to realize the conveying of materials in a continuous flow and stable status. During conveying, the vapor-phase separation technology is adopted to effectively separate materials from delivery gas. The small amount of dust will be collected uniformly, and most materials will enter the extracting tank. Through the PLC central control, the system is able to realize automatic switching between different pipes and change and optimize conveying parameters according to different materials and different paths, so as to be suited to remote conveying of different materials.

A. Positive pressure conveying is employed to realize remote conveying of materials from one container to multiple containers.

B. The fan is used as the conveying energy to achieve high output and low energy consumption.

C. The dust-free feeder realizes dust-free feeding of raw materials.

D. The sender can adjust the air supply amount to ensure the delivery phase density of materials inside the pipe and avoid pipe blocking.

E. The material pipe is provided with pipe cleaner to ensure that there is no residue in the pipe.

F. The switcher adopts servo technology to realize accurate switching between one pipe and multiple pipes, featured by small floor space and no energy consumption during switching.

G. The system can realize CIP and drying.