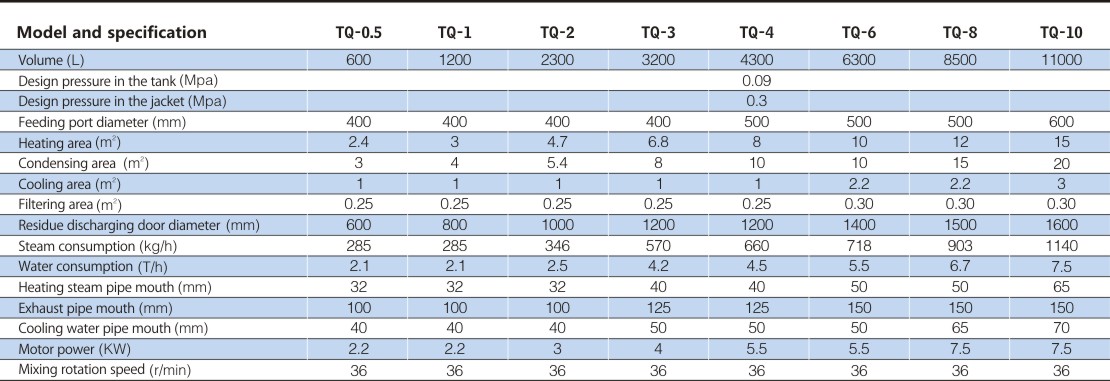

The equipment is applicable to the operations such as decoction of plants and animals at normal pressure and high pressure, warm soaking, hot reflux, forced circulation, percolation, aromatic oil extraction and organic solvent recovery in pharmacy, biology, beverage, food, chemical industry, etc. It is especially suitable for dynamic extraction or counter-current extraction, with short operating time and a high liquid medicine content.

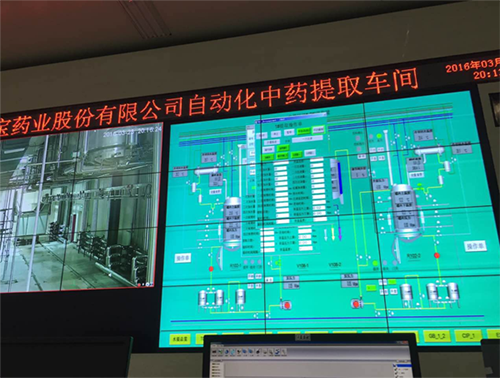

1. Real time control management of process status.

2. Process setting make processed control be more

perfect.

3. Simple and easy application interface for

operation.

4. Process parameter is detected in-place, showed

real time and saved as a file.

5. Real time analyze in-place and solve the problem

in-place and history referred.

6. Strengthen management of production data, ensure

the production quality.

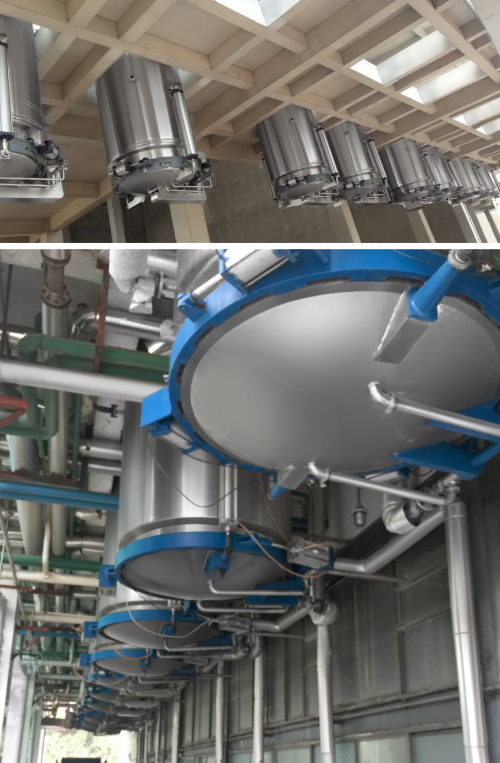

The tank body is equipped with the CIP automatic rotary spray cleaning ball, thermometer, pressure gauge, explosion-proof aperture lamp, sight glass, quick open type feeding inlet and etc., ensuring convenient operation and complying with the GMP standard. The cylinder inside the equipment is made of imported 304 or 316L.

Extraction tank, defoamer, condenser, cooler, oil-water separator, filter, cylinder control desk and other accessories.

MAIN FEATURE

1. The excellent residue discharging door adopts double-cylinder opening and closing and the multi-point locking structure, featured by stable and controllable opening and closing, safe locking and no leakage.

2. Self-locking safety function: After locking, the possibility of automatic dropping and leakage will not occur even if power or gas is cut off.

3. Rapid discharging of extracts: It is provided with the unique filtering structure, which can basically solve the problems of residual medicines blocking the filter screen and hard discharging.

4. The bottom cover is provided with the heating function to make sure there is no dead corner inside the tank and enhance the extraction efficiency per unit time.

5. The bottom cover steam backlash control system avoids steam backlash and prevents the occurrence of tank bursting.

6. The unique oil-water separator increases layering space and time of volatile oil in the separator so as to effectively separate oil from water.

- Discharge door adopts three cylinder rotary self-locking quick open door, double cylinder open/close, cylinder push the locking by rotary, slope wedge block self-locking, which can solve problems of leakage and detach resulted from the unsteady compressed air pressure.

- Seal ring of discharge door adopts special shape, the seal ring gets tighter when liquid column static pressure or vessel pressure is high.

- Discharge door adopts special structure, which substantially reduce the occurrence of lock leading by metal contraction.

Note: After the TQ multifunctional extracting tank is added with necessary devices, a dynamic extraction system can be formed.